Understanding 5-Axis CNC Machining and Its Advantages

Introduction

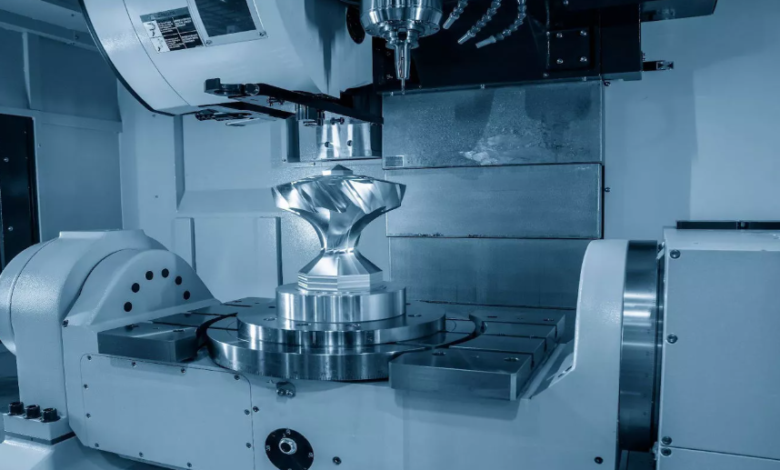

Modern manufacturing increasingly demands precision, complexity, and efficiency. One of the most advanced technologies in this field is 5-axis cnc machining. This technique allows manufacturers to produce highly intricate components with superior accuracy, making it essential for industries such as aerospace, automotive, medical devices, and robotics.

By leveraging 5-axis cnc machining, companies can reduce production time, minimize errors, and create parts that would be impossible using traditional methods. This article explores its benefits, applications, and factors to consider when selecting a machining provider.

What is 5-Axis CNC Machining?

5-axis cnc machining refers to the process where cutting tools move along five different axes simultaneously. Unlike traditional 3-axis machines that move along X, Y, and Z axes, 5-axis machines include rotation around two additional axes. This allows for more complex geometries and angled cuts in a single setup, improving precision and reducing the need for multiple fixtures.

See also: Leveraging Technology to Connect with Target Audiences

Advantages of 5-Axis CNC Machining

Higher Precision and Accuracy

The simultaneous movement along five axes ensures that components are machined with extreme precision. This reduces errors and improves the quality of complex shapes, especially in aerospace and medical applications where tolerances are critical.

Reduced Production Time

5-axis cnc machining can perform complex operations in a single setup. This eliminates the need for multiple repositioning steps, reducing production time and increasing efficiency. Faster production cycles allow companies to meet tight deadlines without sacrificing quality.

Enhanced Surface Finish

Because the cutting tool can approach the material from multiple angles, the surface finish of components is significantly improved. This is important for parts that require smooth surfaces or aesthetic appeal, such as consumer products or medical implants.

Capability for Complex Geometries

5-axis machines can produce intricate designs and curved surfaces that are challenging for traditional 3-axis machines. Components with deep cavities, angled cuts, or irregular contours can be machined precisely, making this technology ideal for advanced engineering applications.

Reduced Tool Wear

The optimal orientation of the cutting tool minimizes stress and wear during the machining process. This extends the lifespan of tools and reduces operational costs, while maintaining consistent accuracy throughout production.

Key Applications

Aerospace Industry

5-axis cnc machining is widely used in aerospace for turbine blades, structural components, and engine parts. The ability to produce precise, complex geometries ensures performance, safety, and compliance with strict aviation standards.

Automotive Components

Automobile manufacturers rely on this technology to create engine components, transmission parts, and custom assemblies. The precise machining reduces errors and improves component fit, enhancing overall vehicle performance and reliability.

Medical Devices

Medical equipment such as surgical instruments, prosthetics, and implants benefit from 5-axis cnc machining. Precision and smooth surface finishes are crucial for functionality and patient safety, making this technology ideal for healthcare applications.

Robotics and Industrial Equipment

Robotics and automation equipment often require complex metal parts with high precision. 5-axis cnc machining allows manufacturers to create components with the exact geometries needed for assembly and operation.

Selecting a 5-Axis CNC Machining Supplier

Experience and Expertise

A reliable supplier should have experience producing parts in your industry. Familiarity with specific standards and component requirements ensures fewer errors and higher-quality output.

Equipment and Technological Capabilities

Check that the supplier has modern 5-axis machines, multi-tool capabilities, and automated systems. Advanced equipment ensures efficiency, accuracy, and the ability to handle complex projects.

Quality Control

Suppliers should implement strict quality control procedures using tools such as coordinate measuring machines, laser scanners, and precision gauges. Consistent inspection guarantees that all parts meet the required specifications.

Communication and Project Support

Clear communication is crucial for successful collaboration. A competent supplier provides technical guidance, regular updates, and rapid responses to inquiries, reducing the risk of delays or misunderstandings.

Reliability and Timely Delivery

Choose a supplier with a proven track record of meeting deadlines. Timely delivery and the ability to manage urgent orders without compromising quality are critical for maintaining production schedules.

Emerging Trends in 5-Axis CNC Machining

Automation and Smart Manufacturing

The integration of AI, IoT, and automated systems into 5-axis machining improves efficiency and enables real-time monitoring. Smart manufacturing reduces errors and optimizes production workflows.

Advanced Materials

Suppliers increasingly work with lightweight alloys, composites, and high-strength metals. 5-axis cnc machining allows the production of parts from advanced materials without compromising precision or durability.

Sustainable Practices

Sustainability is becoming a priority in manufacturing. Efficient use of materials, energy-saving equipment, and recycling initiatives are helping suppliers reduce their environmental impact while maintaining high-quality standards.

Conclusion

5-axis cnc machining represents a significant advancement in precision manufacturing. Its ability to produce complex geometries, enhance surface finishes, reduce production time, and improve accuracy makes it an indispensable technology across multiple industries. By choosing a reliable and experienced supplier, businesses can achieve cost efficiency, maintain product quality, and meet tight production schedules. As automation, advanced materials, and sustainable practices continue to shape the manufacturing landscape, 5-axis cnc machining will remain a cornerstone of modern production solutions.