FastTurn’s Engineering Capabilities for High-Precision PCB Manufacturing

In today’s rapidly advancing electronics industry, high-precision PCB manufacturing is essential to ensuring performance, reliability, and miniaturization. Whether it’s aerospace, automotive, or medical electronics, the demand for tighter tolerances, higher layer counts, and cleaner signal integrity continues to grow. Meeting these expectations requires not only cutting-edge fabrication technology but also deep engineering expertise—something FastTurn PCB delivers consistently.

High-Precision Industry Needs

High-reliability sectors such as aerospace, defense, medical, and industrial automation cannot afford even the smallest deviation in board performance. Their PCBs must handle extreme temperatures, vibration, and long-term operation without signal degradation. Traditional pcb manufacturing methods often fall short when microvias, controlled impedance, or fine-pitch BGAs are involved. That’s why companies turn to partners who can meet IPC Class 3 or even military-grade standards with repeatable quality.

FastTurn Technology

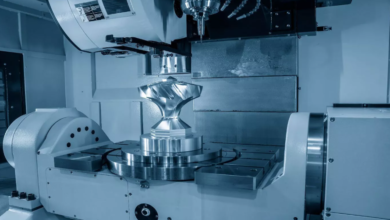

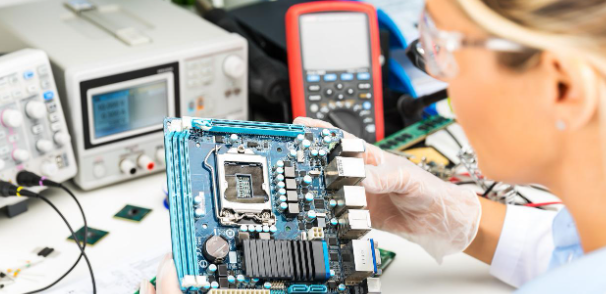

At the heart of FastTurn PCB’s success is its investment in precision-driven technology. The company utilizes advanced laser drilling for microvias, automated optical inspection (AOI), and high-accuracy registration systems to maintain exact layer alignment. Its pcb manufacturing capabilities also include HDI stack-ups, advanced copper plating uniformity, and fine trace/space fabrication down to 2 mils. Combined with a controlled cleanroom environment and statistical process control, these technologies ensure every layer of the board is consistent and defect-free.

Engineering Support System

FastTurn believes precision starts with collaboration. Its in-house engineering team works closely with clients during DFM (Design for Manufacturability) and DFA (Design for Assembly) reviews to prevent errors before they occur. From stack-up recommendations to impedance modeling, this proactive support minimizes rework and accelerates prototype-to-production cycles. For customers building pcb manufacturing for high-reliability engineering applications, this engineering integration ensures that product intent is translated flawlessly into manufacturable outcomes.

See also: Integrating Into Utah’s Thriving Tech Sector

Production Controls

Quality doesn’t just happen—it’s built into every step. FastTurn implements end-to-end process controls, including traceability from raw materials to finished boards. Automated inspection, in-process SPC data, and electrical testing guarantee consistency across batches. The company’s ISO and UL certifications reinforce its commitment to strict international manufacturing standards. These controls make FastTurn a preferred partner for OEMs that require validated reliability for mission-critical projects.

Industry Applications

From high-frequency radar systems and EV control units to life-support medical devices, FastTurn PCB supports a wide range of demanding applications. Its precision-driven approach enables engineers to push design limits while maintaining manufacturability and compliance. FastTurn’s expertise ensures that whether you’re building a first prototype or scaling to production, quality and accuracy remain uncompromised.

Conclusion

In an industry where precision equals performance, FastTurn PCB stands out as a trusted pcb manufacturing partner for engineering teams that can’t afford errors. With advanced equipment, engineering collaboration, and rigorous process control, FastTurn empowers innovators to bring high-reliability designs to life—faster, smarter, and with total confidence.